High-Efficiency 200W Semi-Auto Soldering Station Automatic

Soldering Robot

Introduction

The semi-automatic soldering machine exemplifies the electronics

industry's unwavering pursuit of efficiency and precision. Serving

as a crucial element in electronic component manufacturing lines,

this equipment stands out for its stability and effectiveness,

significantly enhancing both production throughput and product

quality. With the swift evolution of the electronics sector, the

semi-automatic soldering machine has become an essential tool,

seamlessly integrating into modern manufacturing processes.

Features

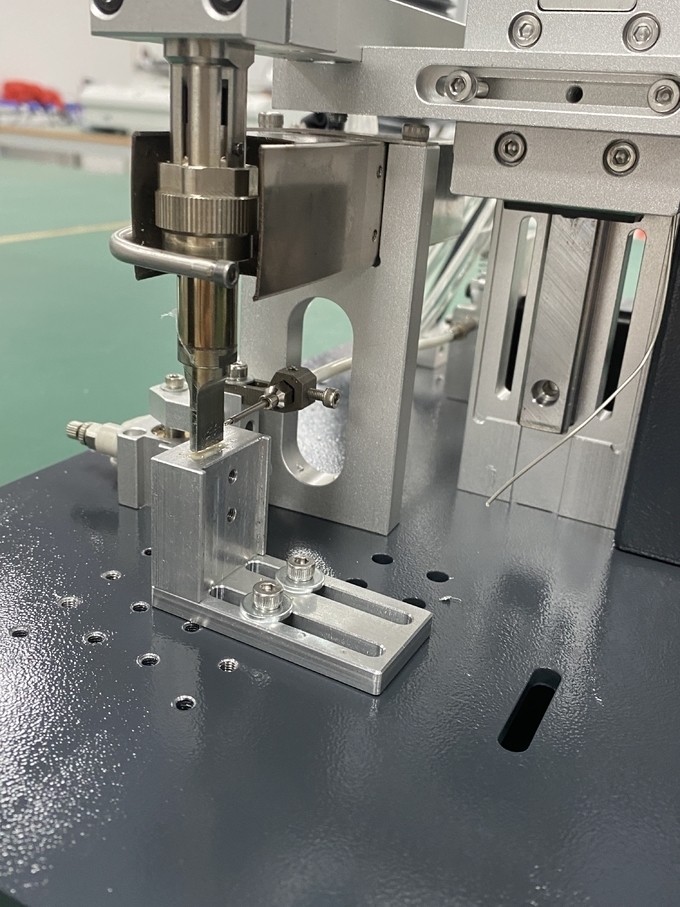

Automated Solder Dispenser:

This soldering station automates the dispensing of solder according

to predefined settings, thereby enhancing efficiency and weld

quality while minimizing manual intervention.

Precision Temperature Control:

Sophisticated temperature management mechanisms ensure consistent,

high-quality solder joints, crucial for reliable electrical

connections.

Rapid Heating System:

High-efficiency heating elements reduce preheat times, optimizing

workflow and boosting productivity.

User-Friendly HMI Interface:

An intuitive LCD display or knob control allows for easy

configuration and monitoring of welding parameters, enhancing

usability.

Flexible Auxiliary Features:

Optional accessories such as smoke extractors create a safer, more

pleasant working environment tailored to various needs.

Versatile Application Range:

Its adaptable design accommodates a wide array of welding tasks,

including electronics, circuit boards, cables, and more,

highlighting its significance in electronic manufacturing.

Semi-Automatic Operation Mode:

Operators maintain manual oversight while the machine integrates

automated features like automatic tin dispensing and heating to

improve efficiency.

Customizable Temperature Regulation:

Equipped with a high-precision temperature control system, it can

be finely tuned to match the specific requirements of various

solders and components.

Multi-Functional Capability:

This system supports a variety of soldering techniques, such as

wave soldering, reflow soldering, and manual soldering, enabling it

to adapt to diverse production needs.

Intuitive Controls:

The user-focused control interface, often featuring a display and

straightforward buttons, simplifies setup and operation, making it

hassle-free.

Application Areas:

Electronic Manufacturing:

Widely utilized in small-batch production and prototype

development, it is suitable for soldering various types of

electronic components.

Repair and Maintenance:

Ideal for repairing electronic equipment, enabling convenient

component replacement and re-soldering.

Advantages:

Efficiency Improvement:

Semi-automatic operation reduces the time required for manual

soldering, thereby enhancing production efficiency.

Consistency:

Automated functions ensure consistent soldering quality, minimizing

human errors.

Flexibility:

Suitable for a multitude of soldering tasks, it can cater to

different production requirements.

Technical details

| Product Name | Semi-auto soldering station |

| Model No. | HS-668 |

| Power supply | Single phase, 220V 50/60Hz |

| Air pressure | 0.2-0.6MPa(Use clean dry air) |

| Control mode | PLC+touch screen |

| Temperature | (-10)-(+60℃)No wind, no dust |

| Soldering control switch | Pedal switch |

| Machine size | L410*W350*H500MM |

| Weight | 15 KG |

Product Details

PLC touch-screen all-in-one machine

Soldering tips of different sizes can be configured