Features

1. The X-ray source adopts 80KV enclosed X-ray tube, stable

quality, don’t need maintenance.

2. Use public company Shanghai IRay,17-inch ultra-clear digital

flat-panel X ray detecting probe,

eliminates the traditional scanning detectors.

3. Ultra fast counting, scan 4 pcs 7 inch reel or 1 pc 15 inch reel

only need 10 seconds.

4. Max can count 17inch (430mm)tape reel, including the a

moisture-proof bag or Jedec packed tape

reels.

5. The patent deep learning algorithm with independent property

rights, accumulate data to the cloud

database and share it with all machines.

6. The machine will scan the bar-code and counting the reels at the

same time, don’t need manual scan the bar-code, and the

corresponding label will be printed immediately when any reel is

taken out, without mistakes.

7.Support the docking of MES, ERP, WMS and other systems, and

digitally manage the material warehouse. Software algorithm is

permanently updated.9. Compared with traditional counting machine,

it greatly improves the efficiency and accuracy, saves manpower,

and greatly shortens the time of material in and out of the

warehouse.

Specification

| Product name | Offline X-Ray SMD Counter |

| Model | DS-3000 |

| X Ray Tube | Type | Enclose type, micro focal spot |

| Tube voltage | 80kV |

| Tube current | 700μA |

| Focal spot size | 30μm |

| Flat-table testing probe | Type | HD digital table |

| Effective area | 430*430mm |

| Pixel size | 140μm |

| Resolution | 3072*3072 |

| Tape reel | Max size | 17 inch(approx 430mm) |

| Max height | 85mm |

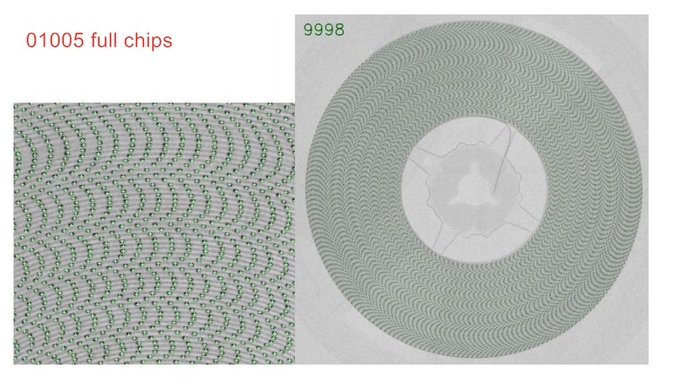

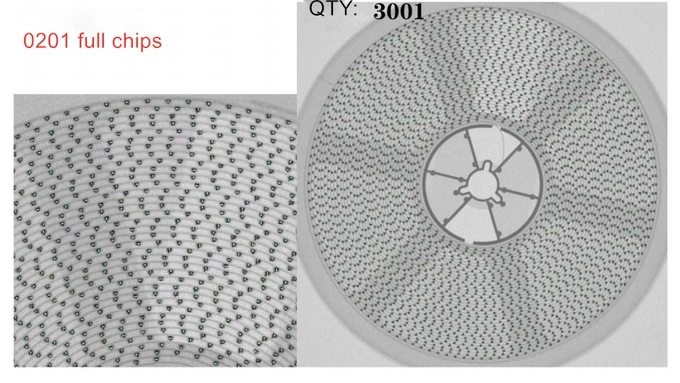

| Min components | 01005 |

| Counting speed | 10 seconds each time |

| Counting accuracy | >99.95% |

| Functions | Bar-code auto scanning | Support QR code,bar-code |

| Label printer | Print corresponding label |

| Management system | MES,ERP,WMS |

| Machine basic information | Size | 1067*1335*1968mm |

| Weight | 950KG |

| Power supply | AC110V/220V,50/60Hz |

| Max power | 800W |

| Industrial PC | I7-6700 CPU, 8G RAM, 240GB SSD |

| Monitor | 24inch HDMI display |

| Security | Radiation | None,standard <1uSv/hr |

| Rear side door lock | Once open the door, the X ray tube power off immediately |

| Table anti-collision protection | When the table extended, there is a steel plate around it to

prevent deformation by impact |

| Safety grating | Equipped |

| Emergency button | Equipped |

Artificial intelligence deep learning algorithm

The counting software uses an artificial intelligence deep learning

algorithm, which does not need to bind

components and algorithms, but uses AI to automatically identify

components and automatically apply

algorithms. The algorithm can learn the data of the components that

have been clicked, such as:

1. The ratio of length to width;

2. The angle of each corner of the component;

3. The slope between the internal to external components;

4. The internal to external components The deformation law of the

device image and so on.

As the number of counting of components increases, the result of

counting becomes more and more

accurate. It is easy to deal with similar components and larger

reels.

Applications

Electronics Manufacturing:

- Widely used in the assembly of electronic devices, such as

smartphones, computers, and consumer electronics, to ensure

accurate component counts.

Quality Control:

- Employed in quality assurance processes to verify that the correct

number of components are present before assembly.

Inventory Management:

- Helps manufacturers keep track of component inventory, reducing

waste and improving production planning.

Research and Development:

- Useful in R&D settings for prototyping and testing new designs,

ensuring that component counts are accurate during trials.