Experience Precision Cutting with Our Top-of-the-Line PCB Router

Machine

Introduce

The PCB Router Machine stands as a highly utilized instrument in

the realm of printed circuit board (PCB) cutting and separation.

Here is an exhaustive overview of its features and capabilities:

Designed specifically for meticulous cutting and efficient

detachment of PCBs, the PCB Router Machine incorporates

state-of-the-art technologies to ensure precise and reliable

outcomes across various manufacturing settings. Its robust build,

combined with an intuitive control system, allows for smooth

integration into production lines, ultimately enhancing overall

productivity and quality.

1.Equipment Components: The PCB Router consists of a frame,

workbench, cutting tools, control and monitoring system, as well as

a motion control system. The frame provides structural support, the

workbench holds the PCBs, the cutting tools perform the cutting

operations, the control system sets parameters and monitors

operations, and the motion system directs the movements of the

tools.

2.Automated Cutting Processes: By using preset cutting paths,

speeds, depths, and other parameters, the PCB Router automates

cutting tasks, reducing the need for manual input and enhancing

productivity and accuracy.

3.Versatile Cutting Techniques: The PCB Router can adapt to various

cutting methods, including linear, V-shaped, circular, and other

techniques, to accommodate a wide range of PCB designs.

4.Precision Cutting Capabilities: It employs precise tools and

advanced technology to ensure accurate cutting according to preset

paths and specifications, maintaining consistent quality.

5.Deburring Function: After cutting, the PCB Router deburrs the

edges, removing burrs and residues, which enhances the quality and

appearance of the board.

6. Efficiency and Cost-Effectiveness: The automated operation and

precision cutting of the PCB Router expedite production, minimizing

the use of human resources and time, reducing waste and damage, and

ultimately resulting in cost savings.

Specification

| Model | VM-400 | VM-600 |

| Machine Dimension | 420x520x860mm | 620x720x1060mm |

| Voltage | 220V 50/60Hz | 220V 50/60Hz |

| Max Cutting Length | 400mm | 600mm |

| PCB Thickness | 0.8~3mm | 0.8~3mm |

| Separation speed | 600mm/second | 600mm/second |

| Separation type | Circular blade/linear blade | Circular blade/linear blade |

| Components height | 0~70mm | 0~70mm |

| Working temperature | 30~55℃ | 30~55℃ |

| Weight | 50kg | 60kg |

Features

Advanced High-Speed Cutting Capability: The PCB Router Machine excels in swift cutting, providing

economic benefits for bulk production runs, regardless of quantity.

Touchscreen-Enabled Precise Alignment: By employing a touchscreen interface for adjusting the cutting

distance, the machine ensures pinpoint alignment with V-slots on

PCBs, delivering accurate and flawless cutting strokes.

Stress-Reduced Panel Division: The integration of both moving and fixed blades during panel

splitting significantly minimizes stress on PCBs, preventing

welding point fractures and preserving structural integrity.

Static PCB, Mobile Blade Operation: During the splitting process, the PCB remains stationary while

the blade moves, guaranteeing consistent quality and precision in

every cut.

Elevated Efficiency & Premium Quality: Compared to manual methods, the machine drastically reduces

stress on welding points, thereby enhancing both operational

efficiency and product quality.

Versatile Cutting Distance Adjustment Range: With a customizable cutting distance range spanning 1 to 100

meters, the machine accommodates a diverse set of customer

requirements, enhancing overall operational efficiency.

Flexible Starting Position Configuration: The ability to set the initial cutting position freely optimizes

cutting layouts, contributing to the machine's longevity and

extended service life.

Counting Functionality for Enhanced Data Management: Equipped with a counting feature, the machine enables

comprehensive post-production data analysis and reporting,

facilitating improved production oversight and traceability.

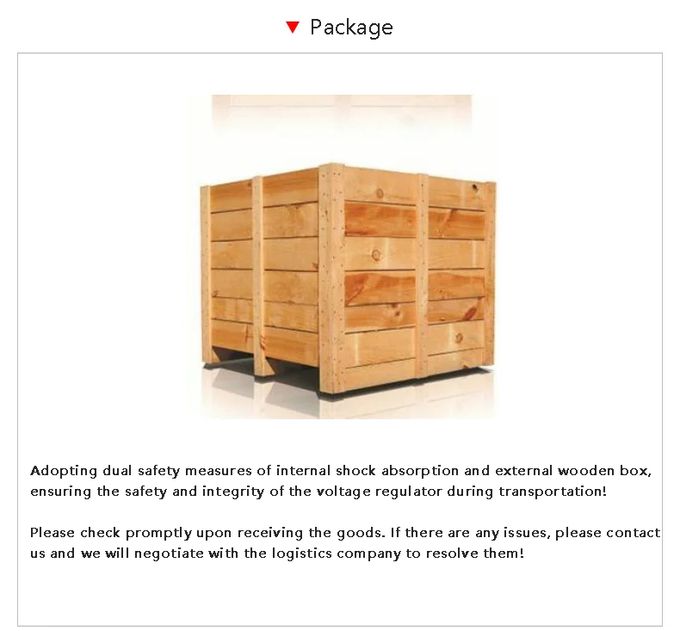

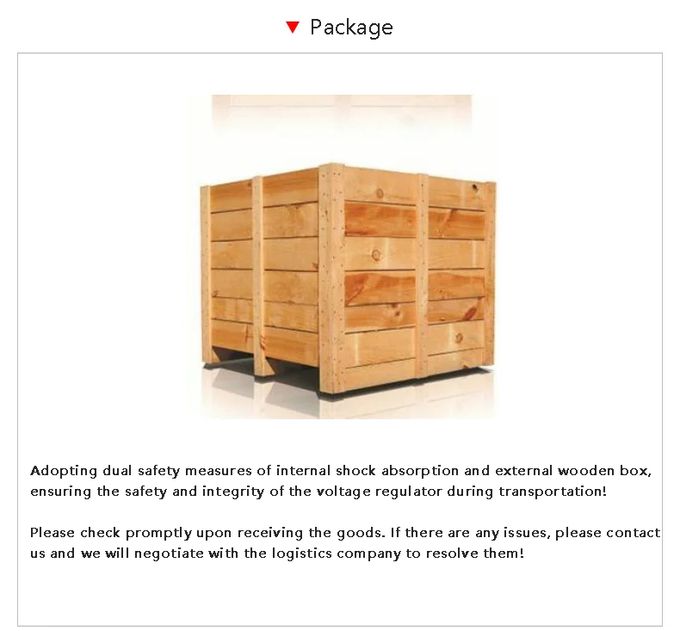

Machine Size

About Packaging