High Quality 304 Stainless Steel SMT Nozzle Cleaner For Safe And

Non-Toxic Cleaning

Introduction

The nozzle cleaning machine revolutionizes nozzle maintenance by

replacing conventional methods such as steel needles or ultrasonic

vibration. It efficiently eliminates stubborn dirt from nozzles

within a brief timeframe, all without causing any damage to the

nozzle itself. Employing non-toxic and eco-friendly cleaning

liquids, this process not only ensures superior cleanliness but

also aligns with environmental sustainability practices.

Features

- Effectively addresses dirt and impurities previously resistant to

ultrasonic cleaning, ensuring complete removal.

- Overcomes limitations posed by increasingly narrow suction nozzle

hole diameters, ensuring thorough cleaning.

- Enhances nozzle longevity through more comprehensive cleaning.

- Preserves nozzle surface coatings and reflective plates, ensuring

no damage during the cleaning process.

- Employs eco-friendly deionized or distilled water for

environmentally conscious cleaning.

- Automates both the cleaning and drying processes for continuous,

hassle-free operation.

- Simplifies and streamlines operation for enhanced user convenience.

- Compatible with a wide range of placement machines, offering

versatility.

- Achieves high efficiency and energy savings by cleaning up to 30

nozzles simultaneously.

Automated cleaning

The equipment uses a mechanical arm and a special cleaning fluid to

fully automate the periodic cleaning of the nozzle of the placement

machine.

Efficient and fast

The cleaning time only takes about 30 seconds, which can greatly

improve the work efficiency of the production line.

Accurate positioning

Equipped with a machine vision system, it can accurately locate the

nozzle position and perform automatic cleaning.

Pollution-free cleaning

The special cleaning fluid can effectively remove the welding slag

and oil stains on the surface of the nozzle without causing any

damage to the nozzle.

Simple operation

The equipment integrates a human-machine interface, and the

operator only needs to simply start the program.

Integrated design

Can be seamlessly integrated with the main placement machine

without the need for additional operating space.

Reliable and durable

Using industrial-grade component design, it has a long service

life.

Energy saving and environmental protection

The cleaning fluid adopts a water-based formula, does not contain

toxic and harmful ingredients, and is environmentally friendly and

recyclable.

Product advantages

1. Reduce the purchase cost of the nozzle

2. Reduce unnecessary labor

3. Reduce product defect rate. Dirty nozzles with weak suction

force can easily cause components to slip and throw away, resulting

in an increase in product defect rate

4. Improve SMT production efficiency

Main Uses

Cleaning the Surface of SMT Nozzles

SMT nozzles will accumulate various pollutants, such as solder

paste residue, dust, etc. during long-term use. SMT Nozzle Cleaner

can effectively remove these pollutants and keep the nozzle surface

clean. This helps ensure the accuracy and stability of the suction

of parts.

Eliminate static electricity

Static electricity is easily generated during the SMT production

process, which can cause dust to adhere to the nozzle surface or

parts to fall off. SMT Nozzle Cleaner contains static eliminators,

which can effectively remove static electricity and improve the

adsorption process.

Extend the life of the nozzle

Regular use of SMT Nozzle Cleaner can remove deposits on the nozzle

surface to avoid excessive wear. This helps to extend the life of

the nozzle and reduce the frequency of replacement.

Improve production efficiency

The performance of the cleaned nozzle is better, which can improve

the accuracy and stability of the part adsorption of the placement

machine, thereby improving production efficiency.

Ensure product quality

A clean nozzle can avoid welding defects caused by contamination,

which is conducive to improving the quality of the final product

Specification

| Model | HS-800 |

| Voltage | Single phase, AC110-220V, 50H60Hz |

| Air pressure | 0.5~0.6Mpa |

| Air source | Pure compressor air |

| Control mode | PLC+Touch Screen |

| Jet pressure | ≤0.4MPa |

| Air wastage | Under 280NL/min |

| Water source | D.I water |

| Water storage | 800cc |

| Water consumption | 300cc/hrs |

| Admission pipe/Drainpipe | φ8/φ6 |

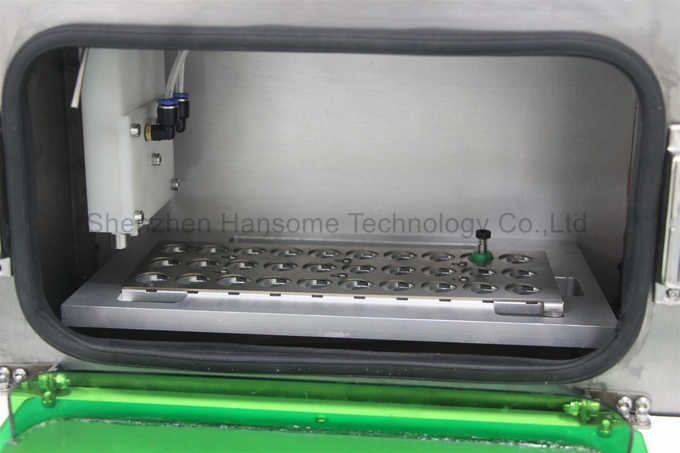

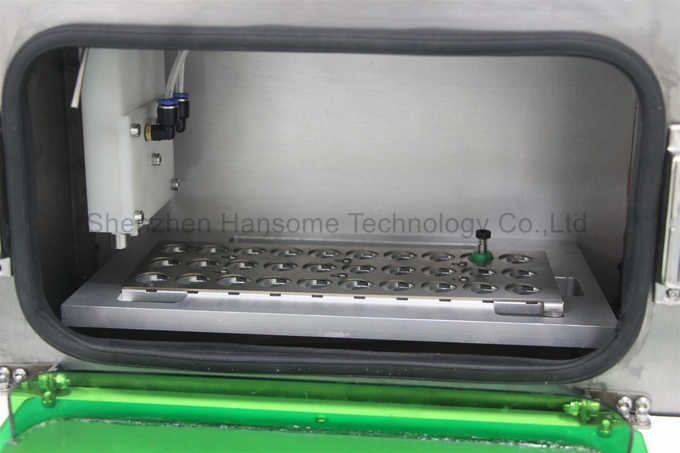

| Nozzle tray | Default 30 nozzles |

| Nozzle size | 01005, 0201-2512inch |

| Noise | 35-60dB |

Machine size

Nozzle Tray