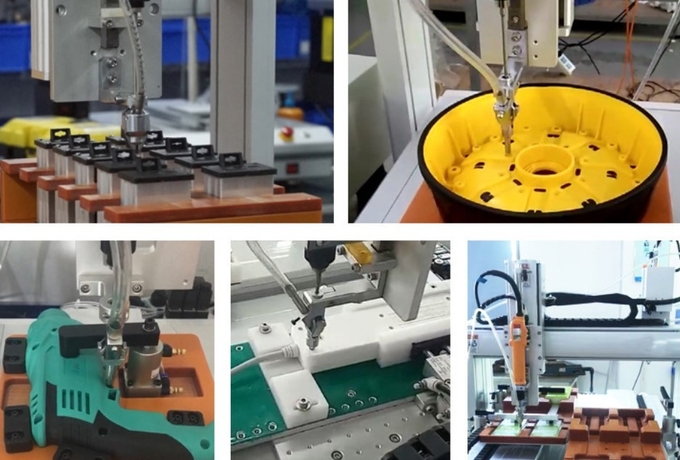

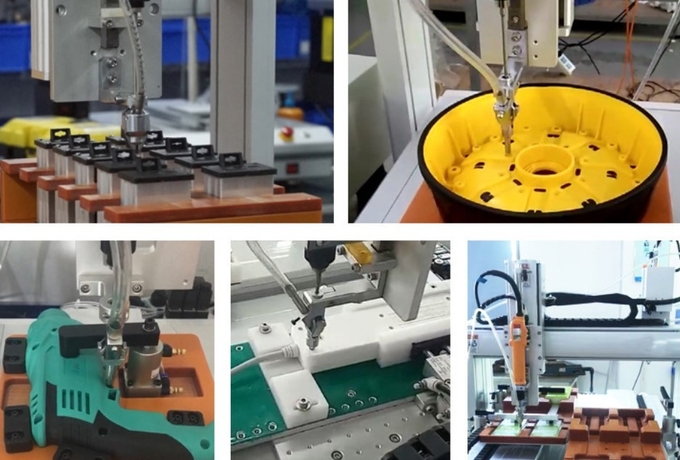

High Precision Screw Fastening Machine for Automated Screw Assembly

with Complex Positioning

The screw machine represents a cutting-edge dual screw driver, dual

platform, and suction-fed automatic screw locking system. It

incorporates a touch screen interface and manual screw head

positioning for effortless location, streamlining programming and

significantly reducing setup time.

This innovative screw locking machine is a game-changer, replacing

traditional manual teaching pendant programming machines. Widely

adopted in the electronics industry, it offers unparalleled

convenience and efficiency.

Designed for compatibility with screws ranging from M1 to M6, it

also accommodates special screws and offers customization options

to meet specific requirements.

Features

- Features suction-type feeding with a single screw feeder and

locking head for efficient operation.

- Designed for desktop use with clear visibility, enabling seamless

integration into automatic production lines.

- Offers 6-axis movement with a generous range of 600300300100100mm, accommodating diverse applications.

- Supports multiple screw bins in suction mode, enhancing versatility

and productivity.

- Equipped with a dual workstation to boost production efficiency and

minimize labor costs.

- Easily adaptable for M1-M6 screws through simple screw guide

changes, with customization options available.

- User-friendly operation allows operators to manage multiple

machines simultaneously, maximizing workflow efficiency.

- Capable of storing numerous processing files, each capable of

holding 1000 screw bit configurations, enabling quick recall and

deployment as needed.

Functions and applications:

Used in automated screw assembly scenarios that require high

precision and complex spatial positioning.

It can achieve coordinated movement of 3 linear axes and 3 rotary

axes to flexibly position screws.

It is widely used in complex product assembly in the automotive,

electronics, home appliances and other industries.

Mechanical structure:

6 independently controllable joints, including 3 linear axes and 3

rotary axes.

It is driven by a servo motor and equipped with a high-precision

encoder to achieve precise positioning.

A screwdriver head is installed at the end of the robotic arm to

achieve high-precision tightening of screws through precision

control.

Equipped with an automatic screw supply device to complete the

entire screw assembly process.

Control system:

Industrial-grade PLC or motion controller is used for centralized

control and program programming.

It can realize 3D spatial trajectory planning to ensure smooth and

collision-free movement of the robotic arm.

Equipped with a human-machine interface, it can realize the design,

storage and call of operating programs.

It has real-time monitoring and feedback in multiple dimensions

such as torque, position, and speed.

Performance characteristics:

6 degrees of freedom, which can realize a variety of complex

spatial postures for screw assembly.

High repeatability, usually within ±0.1mm.

High working efficiency, up to 80-120 times/minute screw assembly

speed.

Suitable for screws of different sizes and materials, strong

compatibility.

High degree of automation, greatly improving production efficiency

and product quality.

Specification

| Model | HS-DH6331 |

| Production name | Automatic Screw Locking Machine |

| Moving range(X/Y1/Y2/Z) | 600*300*300*100*100mm |

| X/Y1/Y2 axis moving speed | Closed loop motor :1-800mm/s |

| Z axis moving speed | Closed loop motor: 1-300mm/s |

| X/Y1/Y2 axis max load | Closed loop motor: 5KG |

| Z axis max load | Closed loop motor: 3KG |

| Power supply | AC110V/220V, 50/60Hz |

| Repeat accuracy | ±0.02mm |

| Document support | CAD CorelDraw |

| Suitable screws | M1-M6 |

| Machine dimension8 | 880*585*800mm |

| Machine weight | 120kg |

Main parts brand

1, Motor: Shinano

2, Guide: Hiwin

3, Photoelectric switch: Omron

4, Power supply: Meanwell

Item | Screw Locking Machine |

Package | 1 set into one wooden carton as safety condition |

External Dimension | 8800*585*800mm |

Weight | about 120kgs |

Delivery | about 15-20 working days |

Payment | D/P, T/T, Western Union, MoneyGram |

Port | Shenzhen |

| A.By Courier: 4-7 Working days by special offer |

B.By Air: 7 Working days at appointed airport |

C.By Sea: 20-25 Working days at appointed port |