High Speed SMT Cleaning Equipment for SMT Nozzle Cleaning with PLC

and Touch Screen Control

Introduce

The SMT (Surface Mount Technology) Nozzle Cleaner is a specialized

tool meticulously crafted for maintaining the hygiene and optimal

performance of nozzles employed in the intricate process of surface

mount technology. In the realm of electronics manufacturing, these

nozzles play a pivotal role in precisely dispensing solder paste or

adhesive onto printed circuit boards (PCBs), thereby ensuring the

quality of the final product. As such, keeping the nozzles spotless

and in peak condition is paramount for maintaining production

standards and achieving desired outcomes.

Features and Functions:

Efficient cleaning

Can quickly and effectively remove solder residues and other

impurities on the nozzle to maintain the cleanliness of the nozzle.

Automated operation

Some models can achieve automated cleaning, reduce manual

intervention and improve operating efficiency.

Multiple cleaning modes

Support multiple cleaning methods, such as air blowing, brushing

and ultrasonic cleaning, to meet different cleaning needs.

User-friendly interface

Simple operation, usually equipped with a display and adjustable

parameters for user convenience.

Improve production efficiency

By regularly cleaning the nozzle, reduce the failure rate and

reduce downtime, thereby improving production efficiency.

Application scenario:

Electronic manufacturing

On the SMT production line, the nozzle needs to be cleaned

regularly to ensure the accuracy and consistency of the mounted

components.

Maintenance and maintenance

Used to maintain and maintain equipment and extend the service life

of the nozzle and related equipment.

Small batch production

Particularly suitable for small batch or multi-variety production,

it can clean the nozzle frequently as needed.

Cleaning Principle

High-pressure jet technology utilizes a fine mist of water

particles, generated through continuous pressure that minimizes

water usage, resulting in the formation of 3-10um water droplets.

These microscopic particles effectively penetrate and cleanse dirt

embedded within the narrow inner walls of small nozzle apertures.

Pulsed power technology, on the other hand, harnesses the velocity

of sound (V=360m/s) to create a potent burst of energy that is

injected onto the nozzle. This powerful pulsed injection operates

at a frequency of up to 30 pulses per second, generating a

relentless impact force directly above the nozzle surface. This

continuous pounding action shatters and dislodges both surface and

internal dirt, thoroughly cleansing the nozzle for optimal

performance.

Specification

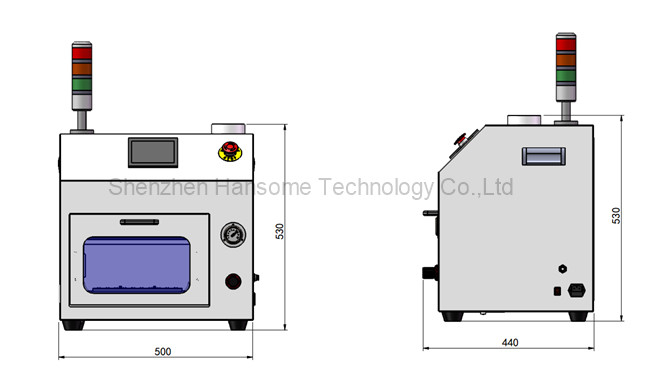

| Model | HS-800 |

| Voltage | Single phase, AC110-220V, 50H60Hz |

| Air pressure | 0.5~0.6Mpa |

| Air source | Pure compressor air |

| Control mode | PLC+Touch Screen |

| Jet pressure | ≤0.4MPa |

| Air wastage | Under 280NL/min |

| Water source | D.I water |

| Water storage | 800cc |

| Water consumption | 300cc/hrs |

| Admission pipe/Drainpipe | φ8/φ6 |

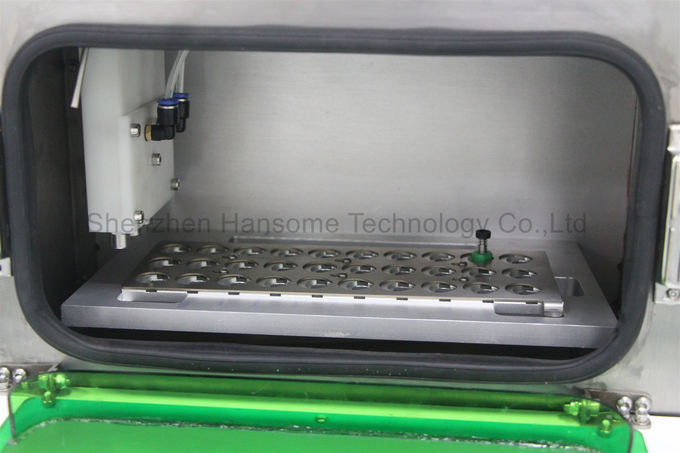

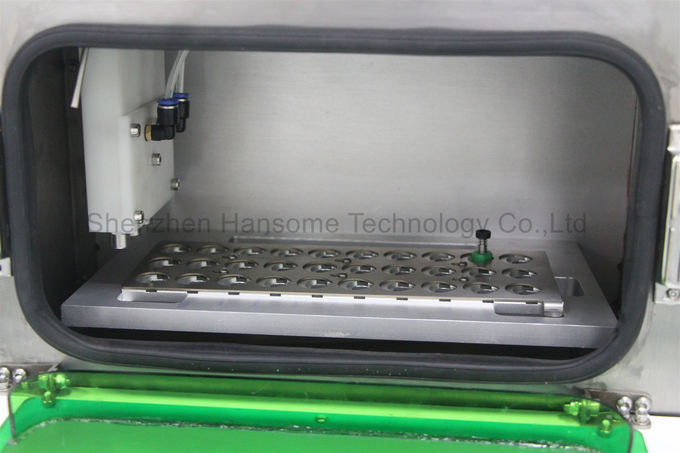

| Nozzle tray | Default 30 nozzles |

| Nozzle size | 01005, 0201-2512inch |

| Noise | 35-60dB |

Product Features

Aesthetically Pleasing Design: Boasting an elegant appearance, the machine body is crafted from

high-precision 304 stainless steel, ensuring durability and a

premium look.

High-Capacity Efficiency: Capable of cleaning up to 30 nozzles simultaneously, this unit

achieves remarkable efficiency while promoting energy conservation.

Versatile Cleaning Capabilities: Designed to accommodate a wide range of nozzle types, including

cross-type, I-shaped, and specialized shapes, it ensures excellent

cleaning performance across the board.

Supersonic Spraying Technology: Equipped with atomized water flow and supersonic spraying

cleaning, it thoroughly eliminates dirt and impurities that may

remain unaddressed by ultrasonic waves, ensuring even the smallest

nozzle holes are left pristine.

User-Friendly Operation: Featuring an intuitive touch screen interface with English

language support, operation is simple and straightforward.

Visual Inspection Window: A convenient inspection window allows for monitoring of the

entire cleaning process, enhancing control and ensuring

satisfaction.

Eco-Friendly Cleaning Solvent: Utilizing D.I. water as the cleaning solvent, this solution is

harmless to all types of nozzles and reflector panels, promoting

environmental sustainability.

Stable and Reliable Control System: Integrated with a touchscreen interface and PLC distributed

control, the unit offers stable and reliable performance, ensuring

consistent cleaning results.

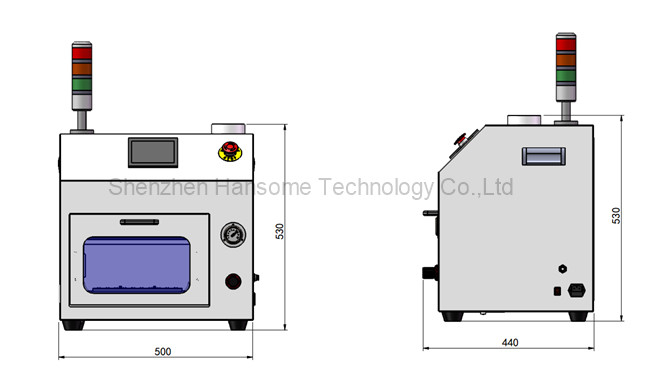

Machine size

Nozzle Tray