High-Precision Knife-type Board Separator Automated PCB Depaneling

Equipment for V-Cut Blade Separation

Introduction

This machine(HS-203) is the blade moving PCB separator, using upper

circular and down linear blade design,before cutting, put the

v-groove onto the linear blade,the upper circular blade moving to

finish spearating, the force stress is relative low, the board

don't need move will protect the components on the board, avoid

damaging.

High-precision separation

The blade movement technology is adopted to accurately separate the

PCB along the V-Cut gap, ensuring high cutting quality and reducing

damage.

High efficiency

Suitable for mass production, saving time and improving production

efficiency through rapid separation.

Easy operation

Humanized design, easy to operate and maintain, suitable for

employees with different technical levels.

Precise control

Adjustable cutting depth and pressure to ensure adaptation to

different types of PCBs.

Safety

Safety protection measures are set to ensure the safety of

operators.

Specifications and functions:

1. Power supply: single-phase AC220V 50-60HZ.

2. Weight: 60KG.

3. Machine size: 770mm (length) * 370mm (width) * 420mm (height).

4. Cutting speed: 300mm/s.

5. Maximum stroke of the knife wheel: 350mm.

6. Fine adjustment of the knife wheel: 0-3mm.

7. The lower knife can be adjusted: 0-2mm.

8. The width of the rear baffle is: 150mm, the maximum PC board

cutting width: 150mm,

the maximum PC board cutting length: 350mm, the thickness of the PC

board that can be cut:

0.6-3.2mm, the thickness between the V grooves: 0.25-2.0mm.

9. The infrared radiation switch is used for safety protection.

When the hand or foreign object is in

the knife movement area, the machine stops working to ensure safe

operation.

10. The machine is driven by a stepper motor, which can be

self-locked and precisely cut and

positioned when powered on. It solves the problem that the travel

point of DC and AC motors

changes after working for a period of time due to inertia.

11. After connecting multiple PC boards with solder, breaking often

damages the circuit or breaks

the electronic parts. Using this machine can avoid damage and

improve work efficiency and quality.

12. The above circular knife walking and cutting can completely

reduce stress, prevent solder joints

from cracking and parts from breaking.

13. The upper circular knife and lower flat knife method is

adopted. The PC board is placed on the

lower flat knife. Once the switch is stepped on, the upper circular

knife moves horizontally to the set

fixed point, and the PC board is cut and divided. The cutting does

not fall off and the incision is

smooth.

14. The upper and lower knives are imported high-speed steel, the

knives are durable, and when the

knives are not sharp, they can be re-grinded, about 2 times.

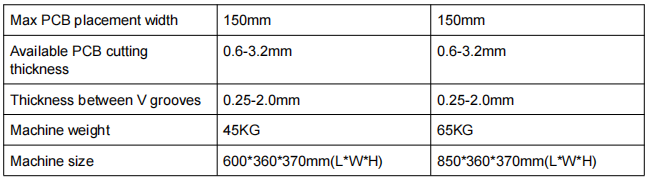

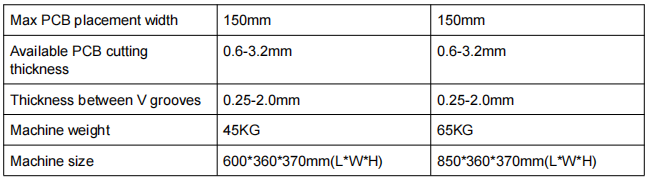

Specification

PCB splitting equipment is mainly used in the following fields

Electronic product manufacturing:

Used to split multi-layer PCBs of mobile phones, tablets,

electronic devices and other products.

It can accurately control the size and position of the split board

to improve the product qualification rate.

Industrial automation:

Applied to the splitting of circuit boards for industrial control

equipment, instruments and other products.

Improve the automation level of production lines and shorten

production cycles.

Consumer electronics:

Widely used for PCB splitting of consumer electronics products such

as laptops and digital cameras.

Ensure the quality of splitting and reduce the rework rate.

Medical electronics:

Applicable to the splitting of circuit boards with high precision

requirements for medical equipment, diagnostic instruments, etc.

Ensure that the splitting process will not cause circuit damage.

Aerospace field:

Applied to PCB splitting with extremely high reliability

requirements in fields such as avionics and aerospace equipment.

Ensure the consistency and stability of the splitting.