Touch Screen SMT Nozzle Cleaner SMT Cleaning Equipment With 304

Stainless Steel

Introduction

The nozzle cleaning machine is a cleaning device that replaces the

traditional cleaning of nozzles by steel needles or ultrasonic

vibration. It can remove the dirt on the nozzles that could not be

removed before in a short time. And the nozzle will not be damaged

during the cleaning process. Since non-toxic and harmless cleaning

liquid is used, the whole process is more environmentally friendly.

Features

- Completely solve the dirt and impurities that are difficult to

clean with ultrasonic waves;

- It will not be cleaned due to the smaller and smaller suction

nozzle hole diameter;

- More thorough cleaning directly extends the life of the nozzle;

- No damage to the nozzle surface coating and reflective plate;

- Use environmentally friendly deionized water or distilled water for

cleaning;

- Automatic continuous cleaning and automatic drying;

- The operation is simpler and more convenient;

- Suitable for various placement machines.

- Max can clean 30 pcs nozzles at one time, achieve high efficiency

and energy saving

Product advantages

1. Reduce the purchase cost of the nozzle

2. Reduce unnecessary labor

3. Reduce product defect rate. Dirty nozzles with weak suction

force can easily cause components to slip and throw away, resulting

in an increase in product defect rate

4. Improve SMT production efficiency

Main Uses

Cleaning the Surface of SMT Nozzles

SMT nozzles will accumulate various pollutants, such as solder

paste residue, dust, etc. during long-term use. SMT Nozzle Cleaner

can effectively remove these pollutants and keep the nozzle surface

clean. This helps ensure the accuracy and stability of the suction

of parts.

Eliminate static electricity

Static electricity is easily generated during the SMT production

process, which can cause dust to adhere to the nozzle surface or

parts to fall off. SMT Nozzle Cleaner contains static eliminators,

which can effectively remove static electricity and improve the

adsorption process.

Extend the life of the nozzle

Regular use of SMT Nozzle Cleaner can remove deposits on the nozzle

surface to avoid excessive wear. This helps to extend the life of

the nozzle and reduce the frequency of replacement.

Improve production efficiency

The performance of the cleaned nozzle is better, which can improve

the accuracy and stability of the part adsorption of the placement

machine, thereby improving production efficiency.

Ensure product quality

A clean nozzle can avoid welding defects caused by contamination,

which is conducive to improving the quality of the final product

Specification

| Model | HS-800 |

| Voltage | Single phase, AC110-220V, 50H60Hz |

| Air pressure | 0.5~0.6Mpa |

| Air source | Pure compressor air |

| Control mode | PLC+Touch Screen |

| Jet pressure | ≤0.4MPa |

| Air wastage | Under 280NL/min |

| Water source | D.I water |

| Water storage | 800cc |

| Water consumption | 300cc/hrs |

| Admission pipe/Drainpipe | φ8/φ6 |

| Nozzle tray | Default 30 nozzles |

| Nozzle size | 01005, 0201-2512inch |

| Noise | 35-60dB |

Machine size

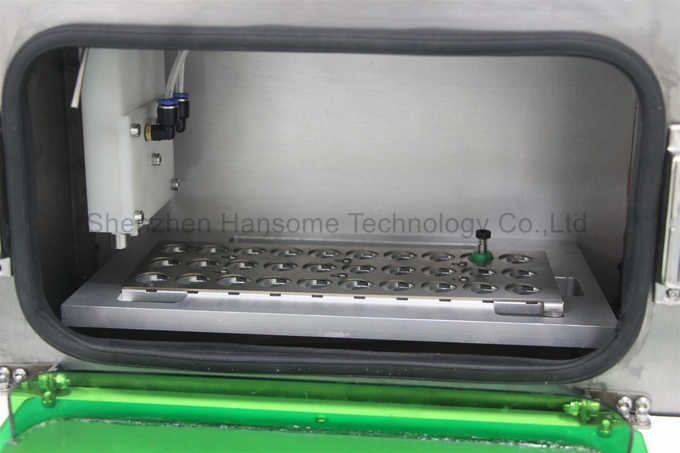

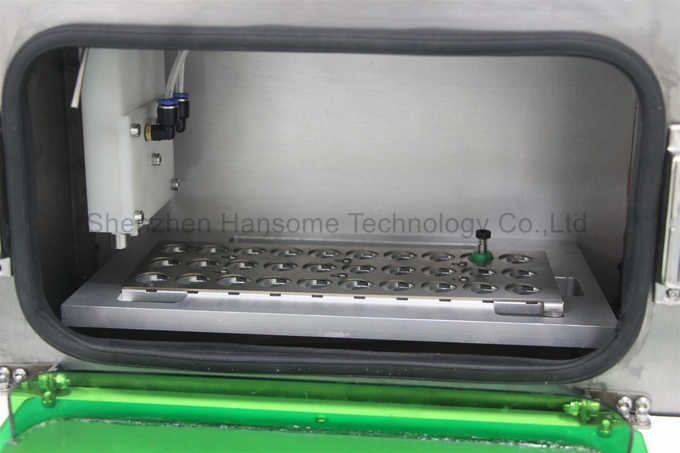

Nozzle Tray