High Speed SMT Cleaning Equipment SMT Nozzle Cleaner With PLC And

Touch Screen Control

Introduce

SMT (Surface Mount Technology) Nozzle Cleaner is a device

specifically designed to clean nozzles used in surface mount

technology. In electronics manufacturing, SMT nozzles are used to

accurately apply solder paste or adhesive to printed circuit boards

(PCBs), so keeping the nozzles clean and in good condition is

critical to production quality.

SMT Nozzle Cleaner usually has the following features and

functions:

1.Cleaning nozzles: SMT Nozzle Cleaner can effectively clean

residues on the surface of SMT nozzles, such as solder paste,

adhesives, particles, etc., by using specific cleaning media or

solvents. It can clean the nozzle by spraying, soaking or brushing

to ensure that the nozzle surface is dust-free and pollution-free.

2.Automated operation: SMT Nozzle Cleaner usually has automated

operation functions and can perform the cleaning process through

preset programs and parameters. It may have functions such as

automatic feeding, cleaning, discharge and drying to improve

cleaning efficiency and reduce manual intervention.

3.Multiple cleaning methods: SMT Nozzle Cleaner can provide a

variety of different cleaning methods to adapt to different types

and sizes of nozzles. Common cleaning methods include jet cleaning,

ultrasonic cleaning, rotating brushing, etc. These methods can be

selected based on the characteristics of the nozzle and usage to

ensure thorough cleaning results.

4.Control and monitoring: SMT Nozzle Cleaner usually has a control

system and monitoring functions to monitor the parameters and

status of the cleaning process. It may have functions such as

temperature control, cleaning time control, liquid level

monitoring, etc. to ensure the stability and consistency of the

cleaning process.

5.Maintenance and Care: SMT Nozzle Cleaner may provide maintenance

and upkeep features to ensure long-term reliability and stability

of the equipment. It may have automatic cleaning system self-test

and cleaning fluid replacement reminder functions to facilitate

timely maintenance and upkeep.

Cleaning Principle

High-pressure jet technology: A, fine water mist particles,

continuous pressure to reduce water, resulting in 3-10um particles

of water mist to clean the dirt into the inner wall of the small

nozzle aperture.

Pulsed power: B, Sound velocity (V=360m/s) forms a powerful pulsed

power injection onto the nozzle, which can reach 30 pulse frequency

per second, forming a continuous impact force above the nozzle to

be cleaned. Smash the surface and internal dirt for cleaning

purposes.

Specification

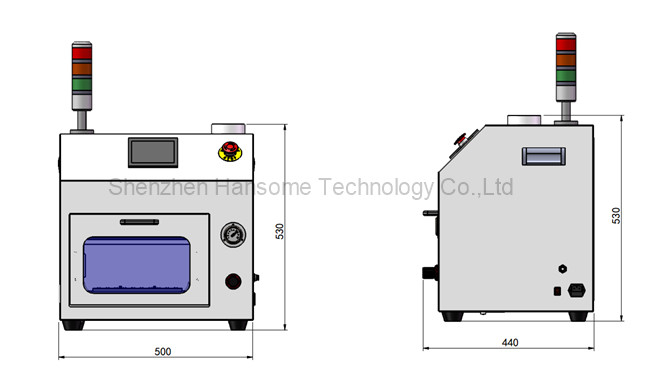

| Model | HS-800 |

| Voltage | Single phase, AC110-220V, 50H60Hz |

| Air pressure | 0.5~0.6Mpa |

| Air source | Pure compressor air |

| Control mode | PLC+Touch Screen |

| Jet pressure | ≤0.4MPa |

| Air wastage | Under 280NL/min |

| Water source | D.I water |

| Water storage | 800cc |

| Water consumption | 300cc/hrs |

| Admission pipe/Drainpipe | φ8/φ6 |

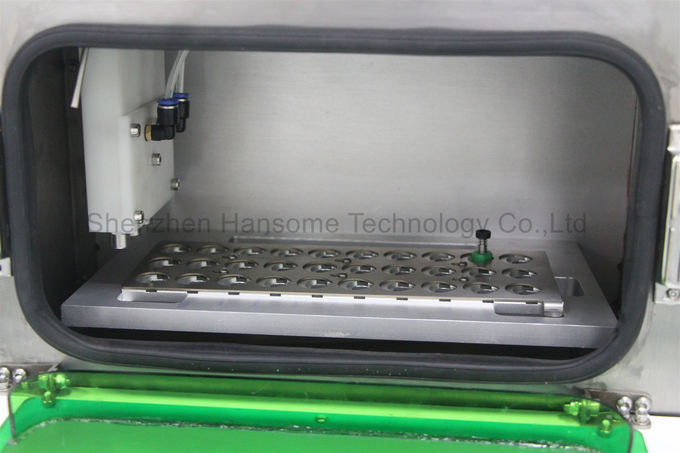

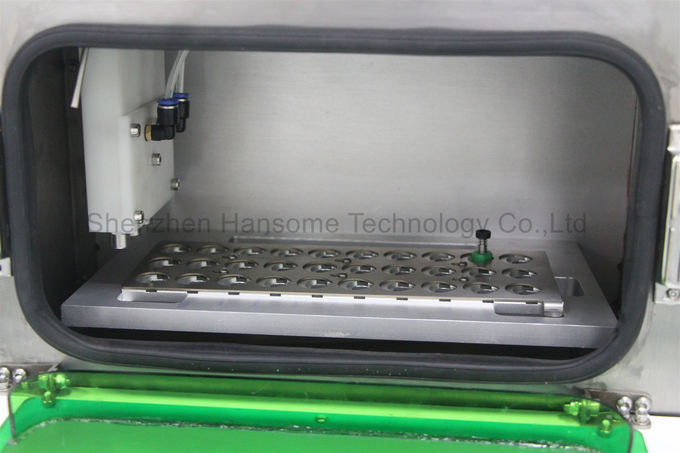

| Nozzle tray | Default 30 nozzles |

| Nozzle size | 01005, 0201-2512inch |

| Noise | 35-60dB |

Product Features

1, Elegant appearance, high precision 304 stainless steel machine

body.

2, Max can clean 30 pcs nozzles at one time, achieve high

efficiency and energy saving.

3, Suitable for cleaning all kinds of nozzles, also have good

cleaning performance for cross type, I-shaped, and special shape

nozzles.

4, The atomized water flow equipped with supersonic spraying

cleaning to completely clean the dirt impurities which the

ultrasonic waves can not clean it all, ensure the clearness even

very small nozzle holes.

5, Easy operation, English is available.

6, Inspection window which can watch the whole cleaning process.

7, Using D.I water as cleaning solvent,not harmful for all types of

nozzles and reflector panel.

8, Touch screen + PLC distributed control, stable and reliable

performance

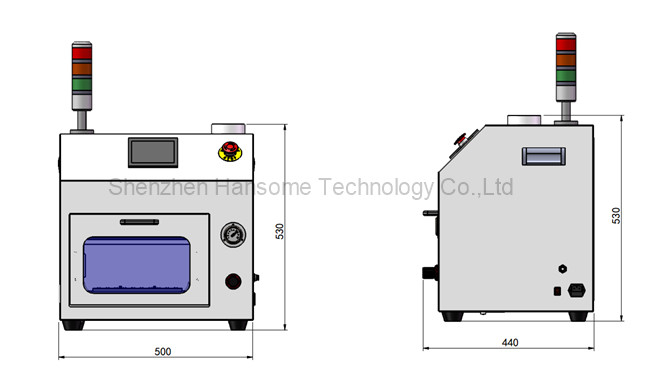

Machine size

Nozzle Tray