SMT Machine Parts Precise Wave Peak Shape Wave Soldering Impeller

for Accurate Soldering

Introduce

Nitong wave soldering cast iron impeller shaft and impeller are

made of cast iron, and the shaft is made of stainless steel 304. It

is used to stir tin in wave soldering furnaces.

Structure

Wave soldering impellers usually consist of bellows, blades and

shafts. Among them, the bellows is the main body of the wave

soldering impeller, and the blades are fixed on the bellows. Due to

the special structure of the bellows, the number of blades of the

wave soldering impeller is usually three. The shaft connects the

wave soldering impeller to the motor of the water pump so that the

wave soldering impeller can rotate.

Features

| High temperature resistance | Wave soldering impellers are usually made of high temperature

resistant materials, which can withstand the heat and pressure

during high temperature welding and maintain stable performance |

| Corrosion resistance | This kind of impeller usually has good corrosion resistance and can

resist the erosion of corrosive gases and liquids produced during

the welding process |

| Excellent heat transfer performance | The wave soldering impeller is reasonably designed to effectively

transfer heat and help the solder melt and flow quickly to ensure

welding quality. |

| Precise wave peak shape | The design of the wave soldering impeller requires a precise wave

peak shape to ensure that the solder forms an ideal welding

waveform during the welding process, thereby improving welding

quality and stability |

| Wear resistance | This kind of impeller usually has good wear resistance and can

maintain stable performance over a long period of use, reducing the

frequency of equipment maintenance and replacement |

| Adjustability | Some wave soldering impellers may have adjustable features that

allow them to be adjusted to specific welding requirements to

achieve optimal performance under different welding conditions |

| Wide applicability | The wave soldering impeller is suitable for different types of

welding equipment and processes. It can be used to weld various

electronic components, PCB boards, etc., and has a wide range of

applications |

Application of wave soldering impeller

The wave soldering impeller is a key component used in swimming

pool water circulation systems. Its main function is to be

installed at the inlet of the water pump, rotate to push water into

the pump body, form a strong suction force, and circulate the water

in the swimming pool to the water treatment system for treatment,

thereby keeping the swimming pool water clean.

Application of wave soldering impeller

The wave soldering impeller is a key component used in swimming

pool water circulation systems. Its main function is to be

installed at the inlet of the water pump, rotate to push water into

the pump body, form a strong suction force, and circulate the water

in the swimming pool to the water treatment system for treatment,

thereby keeping the swimming pool water clean.

Problems and solutions in the use of wave soldering impellers

In daily use, wave soldering impellers will also have some

problems. For example, when the water is unclear, it may be caused

by damaged or missing blades of the wave soldering impeller. At

this time, the wave soldering impeller can be disassembled for

inspection and repair or replacement;

In addition, if the bearings of the wave soldering impeller are

worn or damaged, the entire wave soldering impeller needs to be

replaced. In addition, the wave soldering impeller should be

regularly maintained and cleaned to ensure its normal operation and

extend its service life.

To sum up, the wave soldering impeller plays a very important role

in the swimming pool water circulation system. Its structure

usually consists of a bellows, three blades and a shaft. It

requires regular maintenance and inspection during use to ensure

its normal operation.

二,Cover Plate

Used together with wave soldering impeller

Features

| High temperature resistance | Wave soldering cover plates are usually made of high temperature

resistant materials, which can withstand the heat and pressure

during high temperature soldering and maintain stable performance |

| Prevent oxidation | This cover can effectively prevent the solder from being oxidized

during the welding process, ensuring the welding quality and the

reliability of the welding joints |

| Avoid splashing | The wave soldering cover is reasonably designed to effectively

avoid splashing and spattering of solder and reduce impurities and

defects during the welding process |

| Corrosion resistance | Wave soldering cover plates usually have good corrosion resistance

and can resist the erosion of corrosive gases and liquids generated

during the welding process |

| Easy to clean | This cover has a smooth surface and is easy to clean and maintain,

keeping it clean and extending its service life |

| Wide applicability | The wave soldering cover is suitable for various wave soldering

equipment and processes, and can be used to weld various types of

electronic components, PCB boards, etc., and has a wide range of

applications |

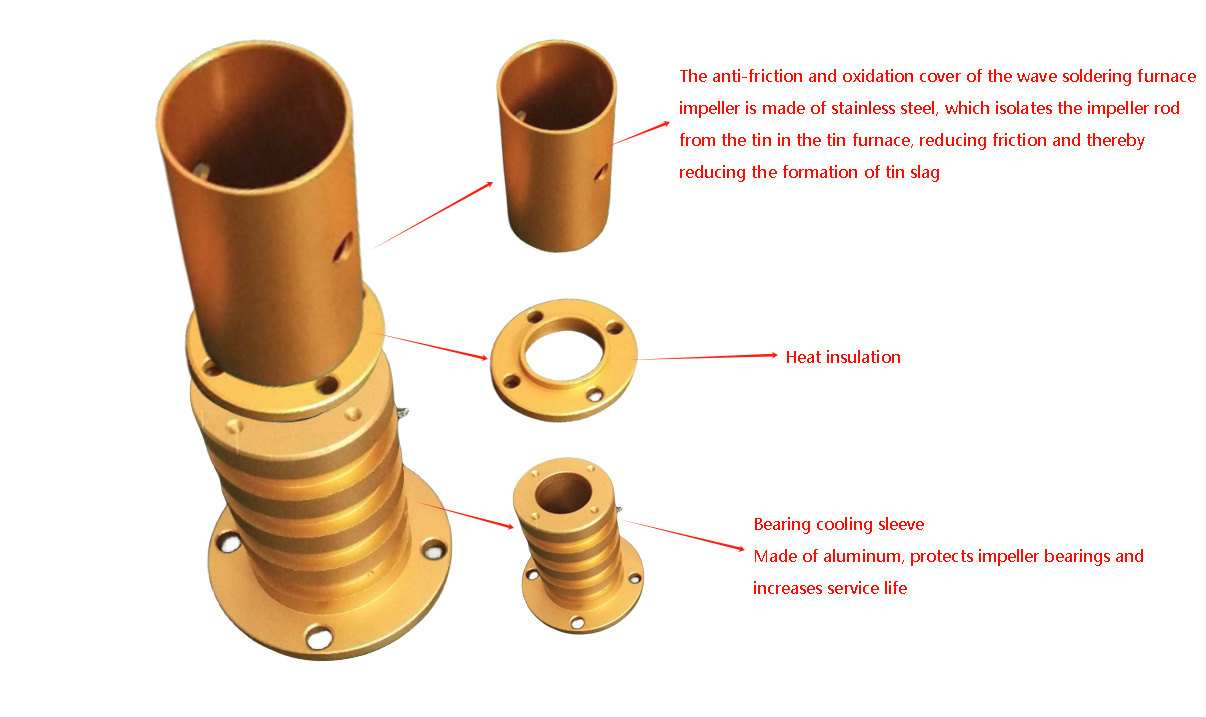

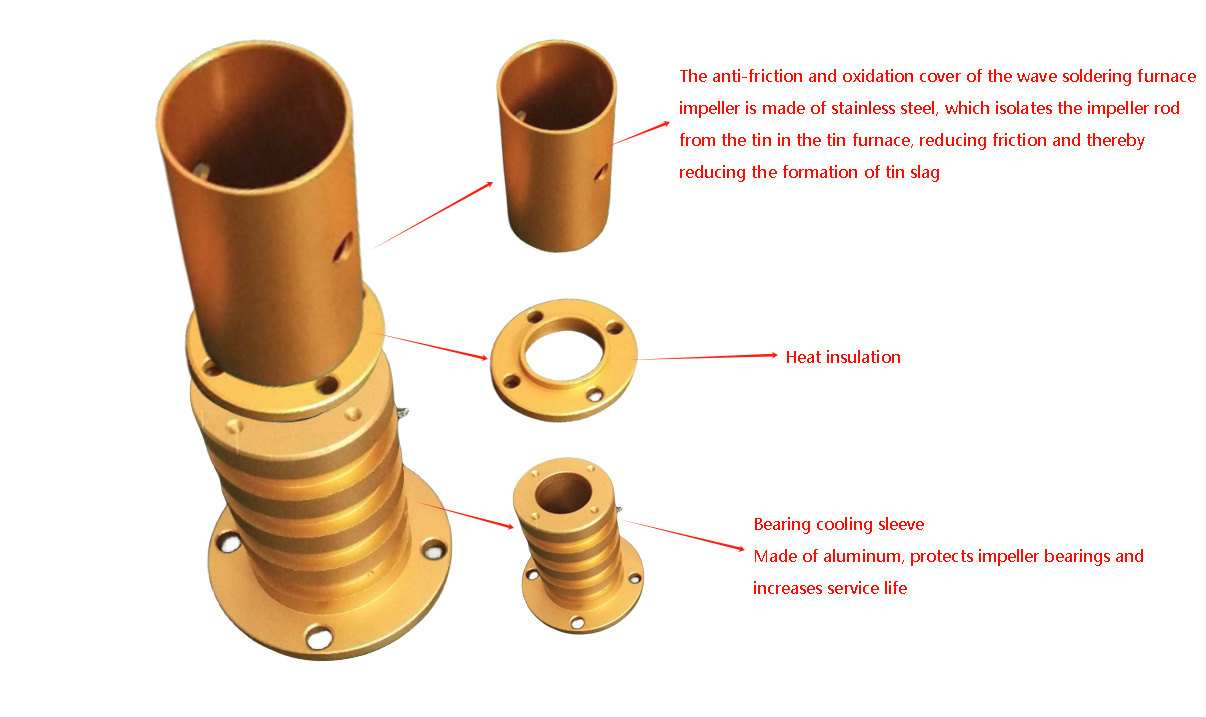

三, Impeller bearing sleeve

About Us:

Shenzhen HanSome Technology Co.,Ltd(HSTECH)was estabilished in 2012

by prefessional and experienced engineer who wroked many years in

EMS company,we specilized in PCB handling equipments at first, then

we develop the PCB depaneling machine and SMT cleaning machine.

HSTECH not only have professional technical team for R&D,but

also have a outgoing and experienced marketing team for research

and develop, grasps products developing directions, updates the

products and technics to meet the continue changing demands. In the

past years,we have been always keep innovating and exploing to make

cost-efficient products to help our customers saving cost and

labor, improving the production efficiency at the same time.

HSTECH set the goal for "High quality and Smart”, that based on the

concept of "Quality-Oriented and Customer-orented", and combined

the industry feature, smart technology persuit for the smart

factory.As for the after-sale service, we insist on

"responsibility", we will take reaction at the first when we got

quality feedbacks,and service our customers all the time.