High-Performance SMT Machine Parts Reflow Condenser For Welding

Introduce

The reflow condenser is a key component of the reflow soldering

process. It is a device that uses the cooling effect to cool and

solidify solder joints.

The cooler usually consists of a cooling tube and a cooling fan.

The cooling tube reduces the temperature of the pad by introducing

gas above or below the reflow oven. At the same time, the cooling

fan can send the gas after welding into the cooler to cool the

welded circuit board. In this way, the reflow condenser can help

the solder joints maintain stable and good quality during the

cooling and solidification process.

Working Principle

The working principle of the reflow condenser is very simple: when

the solder joint melts, the cooling tube provides cooling gas into

the furnace, thereby reducing the temperature of the solder joint.

Likewise, the cooling fan brings cooling gas into the cooler,

causing the board temperature to drop.

In short, the working principle of the reflow condenser is to use

the cooling effect to cool and solidify the solder joints.

Features

| Efficient heat dissipation | It has excellent heat dissipation performance and can quickly

dissipate the heat generated during the welding process to ensure

that the welding temperature is controlled within an appropriate

range. |

| Reliability | This type of condenser is usually made of high-quality materials

and is resistant to high temperatures and corrosion, and can

operate stably for a long time without failure |

| Compact design | To meet the compact layout requirements of modern electronics

manufacturing equipment, reflow condensers often have compact

designs that enable efficient operation within limited space |

Energy saving and environmental protection | Some reflow condensers may be energy-saving and environmentally

friendly. By optimizing the design and using high-efficiency

materials, they can reduce energy consumption and reduce the impact

on the environment |

| Easy to maintain | In order to ensure the reliability and stability of the equipment,

the reflow condenser is usually designed to be an easy-to-maintain

and clean structure, making it convenient for operators to perform

daily maintenance and upkeep |

| Precise control | Some reflow soldering condensers may be equipped with a precise

temperature control system, which can achieve precise control of

the soldering temperature to ensure stable soldering quality and

product performance |

| Safety | Reflow condensers usually have safety features, including

overheating protection, leakage protection and other functions,

which can effectively prevent safety accidents caused by equipment

failure |

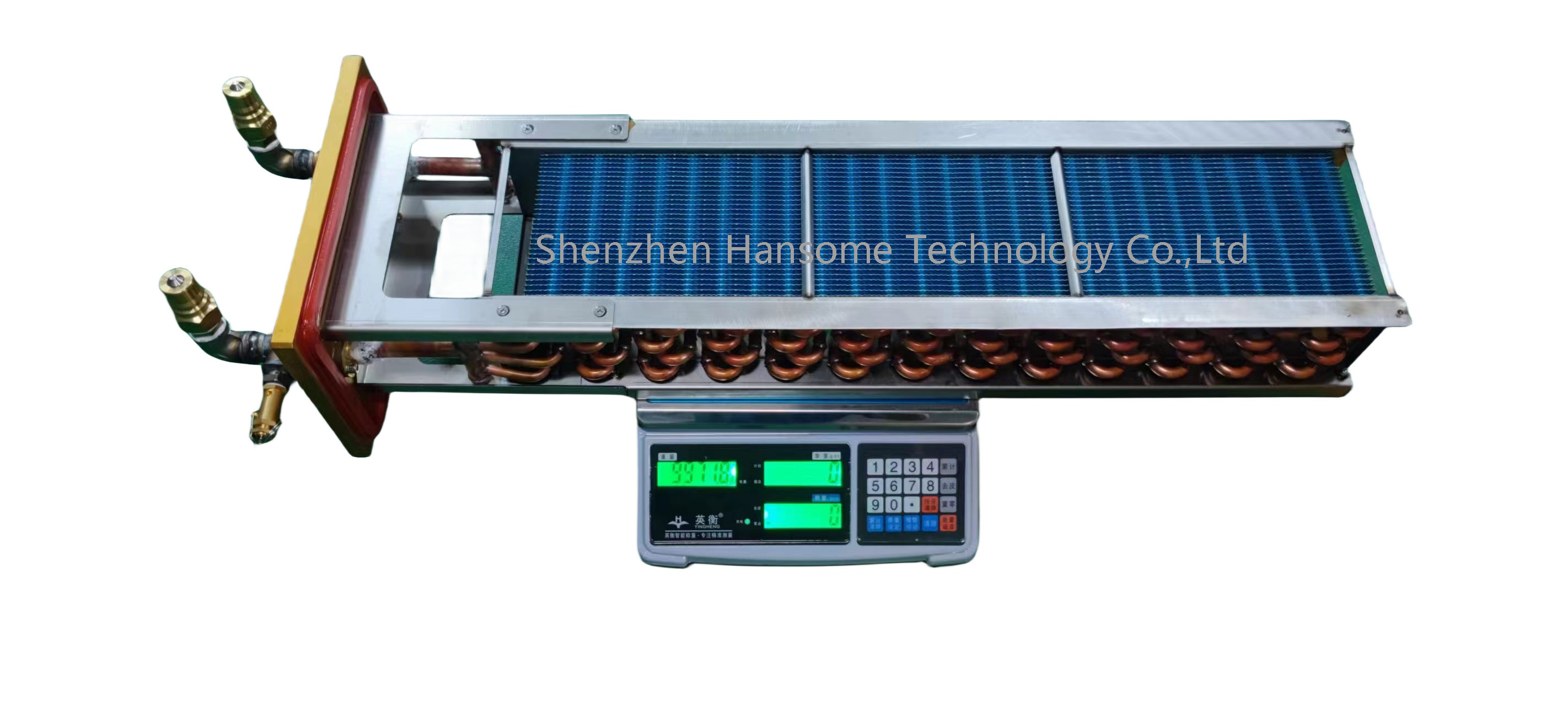

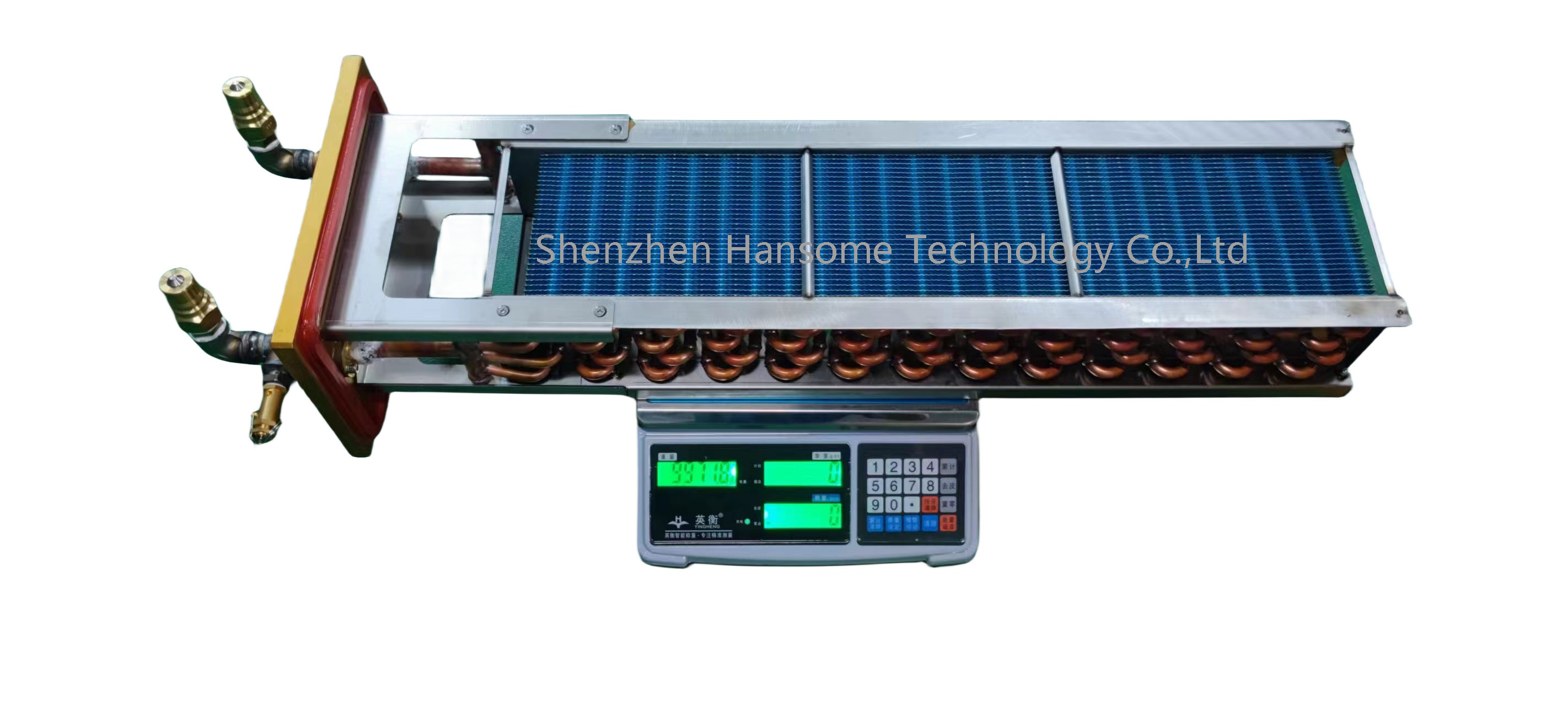

Product Display

Product Physical Display

The importance of reflow condenser

It can help the solder joints quickly cool down and solidify after

receiving heat, thereby ensuring the quality and stability of the

solder joints. Without a reflow condenser, the solder joints may

leave black marks during the cooling process, which will affect the

quality of the solder joints and the electrical connection

performance.

In short, the reflow condenser is an indispensable part of the

reflow soldering process, and its importance lies in maintaining

the quality and stability of the solder joints.

About Us:

Shenzhen HanSome Technology Co.,Ltd(HSTECH)was estabilished in 2012

by prefessional and experienced engineer who wroked many years in

EMS company,we specilized in PCB handling equipments at first, then

we develop the PCB depaneling machine and SMT cleaning machine.

HSTECH not only have professional technical team for R&D,but

also have a outgoing and experienced marketing team for research

and develop, grasps products developing directions, updates the

products and technics to meet the continue changing demands. In the

past years,we have been always keep innovating and exploing to make

cost-efficient products to help our customers saving cost and

labor, improving the production efficiency at the same time.

HSTECH set the goal for "High quality and Smart”, that based on the

concept of "Quality-Oriented and Customer-orented", and combined

the industry feature, smart technology persuit for the smart

factory.As for the after-sale service, we insist on

"responsibility", we will take reaction at the first when we got

quality feedbacks,and service our customers all the time.