Rapid and Compact Heating Solution for SMT Machine Parts with

Heating Wire

Introduce

Heating wire is the most common type of heating element. Its

function is to generate heat after being energized and convert

electrical energy into thermal energy.

Reflow soldering is a group or point-by-point soldering process in

which an appropriate amount and form of solder is placed in the PCB

soldering area in advance, and then the surface mount components

are placed, using an external heat source to reflow the solder to

meet the soldering requirements.The heat required during the

working process is provided by a large number of heating wires

installed in the reflow soldering machine. Therefore, the heating

wire is an important part of the reflow soldering machine.

Feature

| Compact size | Heating wires have a smaller volume compared to traditional heating

elements, making them suitable for designing electronic devices and

circuit boards with limited space |

| Lightweight design | As heating wires are usually made of lightweight materials, they do

not increase the load on the equipment and are suitable for

scenarios that require lightweight design. |

| Rapid heating | Due to its small size and high efficiency in energy conversion, the

heating wire can quickly achieve heating, improving the response

speed and efficiency of the equipment. |

| Low power consumption | Due to the efficient energy conversion of the heating wire, it can

achieve the required heating effect at a lower power, which helps

to save energy and extend battery life. |

| High reliability | The heating wire is fixed on the PCB through surface welding

technology, and the connection is firm and reliable, not easily

affected by vibration and impact, improving the stability and

durability of the equipment |

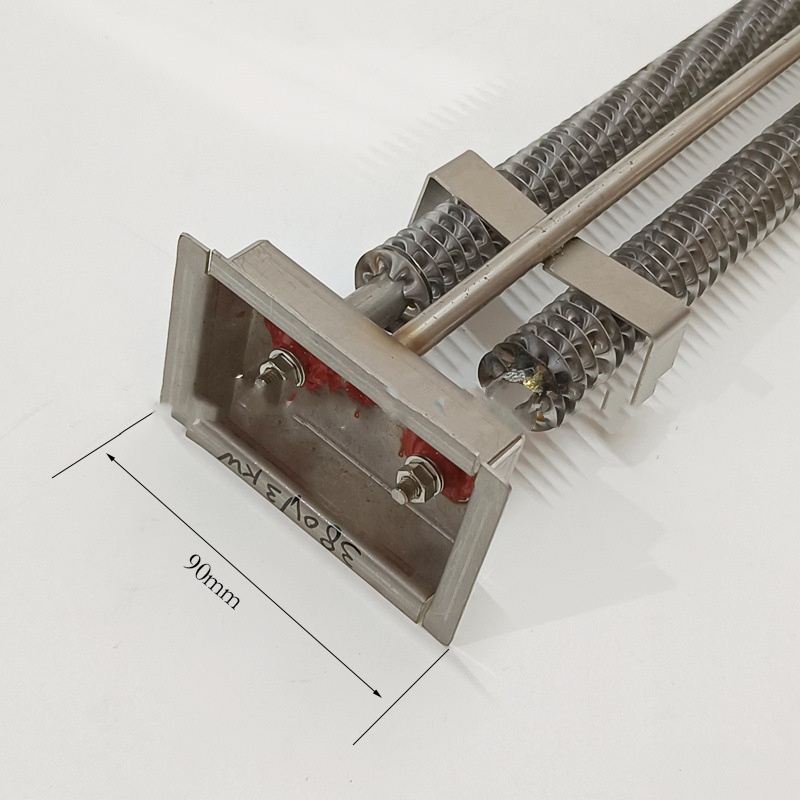

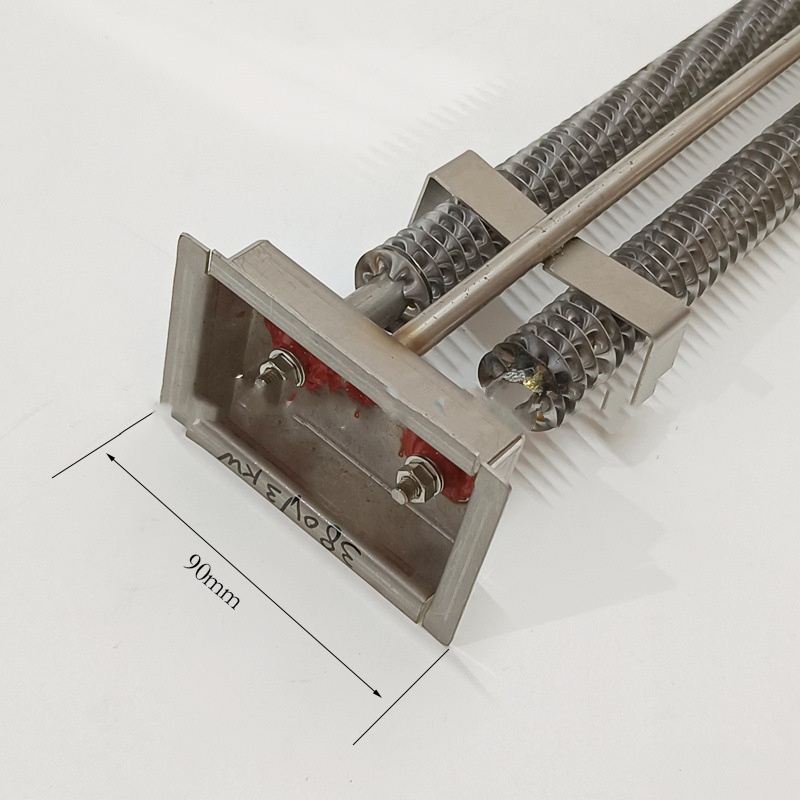

Size selection

Detail display

Product Display

For the treatment of heating wires, the following steps are usually

included:

1.Select appropriate heating wire specifications: Based on specific

application requirements and design requirements, select SMT

heating wires of appropriate specifications, including size,

resistance value, power, working voltage and other parameters.

2.PCB design and layout: In the PCB design stage, it is necessary

to reasonably layout the position of SMT heating wires and ensure

coordination with the layout of other components to ensure the

normal operation and stability of the circuit.

3.Welding process: Use surface mount technology (SMT) to solder the

heating wire onto the surface of the PCB. This usually involves

precise control of welding temperature, time, and pressure to

ensure welding quality and stability.

4.Quality inspection: After welding is completed, the welding

quality is inspected and tested. This includes visual inspection,

welding connectivity testing, as well as resistance and power

testing.

5.Assembly and packaging: Assemble the soldered PCB into the device

and package it to ensure the safety and reliability of the heating

wire and other components.

6.Testing and debugging: Test and debug the entire circuit to

ensure that the SMT heating wire can work properly and meet design

requirements and performance indicators.

7.Application and maintenance: After the equipment is put into use,

regularly inspect and maintain the SMT heating wire to ensure its

normal operation and long-term stability.

By following the above processing steps, the reliability and

performance of SMT heating wires in electronic devices can be

ensured, thus providing an effective heating solution.

About Us:

Shenzhen Hansome Technology Co.,Ltd is a professional SMT board

handling equipment (Loader,Unloader,Buffer Conveyor,Soldering

Machine,Screw Fastening Machine,PCB Depaneling

Machine,etc)manufacturer.

We are a high-tech enterprise with independent intellectual

property riahts, the company is mainly enaaged in the research and

development, production and sales of SMT/THT production line board

handling equipment.

We have more than 10 years' professional SMT industry experience.

With strict production,inspectiondebugging and packaging process,

we insist on providing clients with good service pre-sales,

in-salesand after-sales services. We have professional QC person to

check the quality of the equipment andspare parts. After

manufacturing, all equipment will be carefully tested and debugged

before shipment.